|

Demineralization plants for the generation of fully demineralised within a performance range of 0,5 m3/h. Valve control is available in manually or automatically operated design. Ion exchanger circulation systems for the multiple use of rinsing water in a galvanic station from 3 to 50 m3/h with manual operating or automatic discharge of the regeneration, with mechanical pre-cleaning via rubble and activated carbon filters. |

|

WASTE-WATER TREATMENT Melting plant for the treatment of heavy metal containing waste water with hydroxide precipitation ande monometallic sludge formation. Containers and systems for storage and distribution of chemicals harzardous to water according to §19g of the Water Recourses Act. |

|

Residual metal removal via ion exchanger for the observance of admissible limits for heavy metals at an output of 1-20 m3/h. It's a special kind of ion exchanger (selectiv cation) to remove heavy metals, for example Fe, Ni, Cu, Zn, Sn, from the waste water flow. |

|

Reverse-Osmose plants for manufacture of demineralized water in different output stages. |

|

Gravel filtration of 1-50 m3/h in multi-layer design, manually or automatically operated. It's a special kind of sand filters to remove solids down to 10 - 20 µm from a solution. The sand (gravel) size will be between 1,3 up to 6,3 mm, applications are: well water treatment, pre treatment for Reverse Osmosis pants, pre treatment for drinking water final filtration in waste water plants with selectiv cation filters or as standalone system filtratation of surface water cleaning of cooling water circles |

|

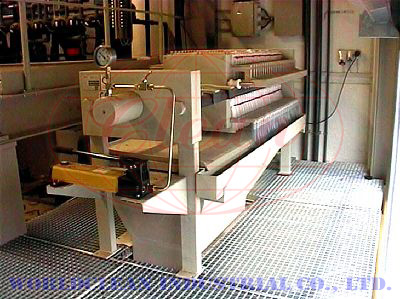

Chamber-filter-press for pressing out of thin sludge (i.e. galvanic mud) with manual operated hydraulic lock or electrical driven plate lock. |

|

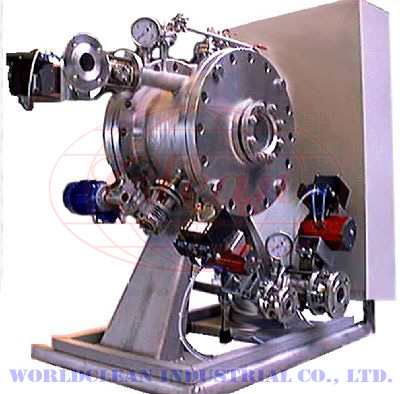

The TCCF - Filter It may be used ro remove solids from 3 - 300 µm from a solution. The solutions could be oil, suspension, water, colors, or some in the food industries. But the material they are made from are only stainless steel. |

|

Retardation plants for the regeneration of acids and process bathes containing contaminating and/or disturbing metal ions, i.e. anodic oxidation bathes and pickling bathes. Good handling, package-type design in 5 different basic types. |

|

Chromic acid recoveries according to the evaporation principle with chromic acid cleaning (foreign metal removal) via cation exchanger. Modular system to be extended without limit. |

|

Microfiltration for service life extension of degreasing bathes. |

|

MSR Technique |

Languages

Products | Waste Water Treatment

- Turnkey Plant Equipmqnt

CE & ISO 9001:2008 Certification